High Thermal Ceramic Paste

E-Mail InquiryProduct Overview

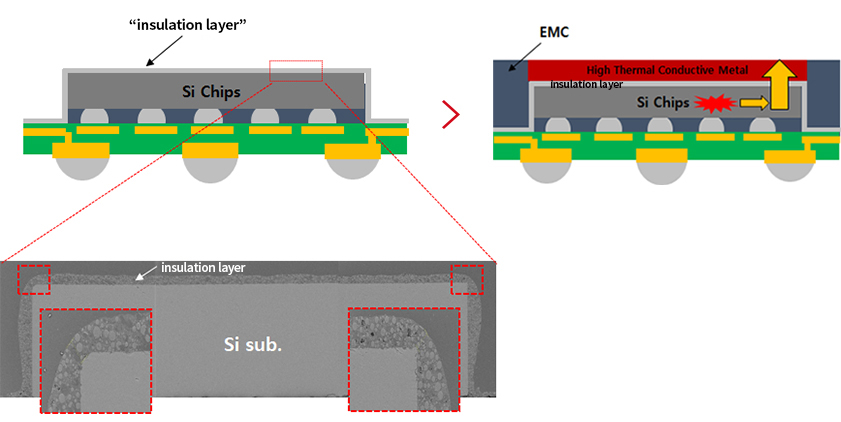

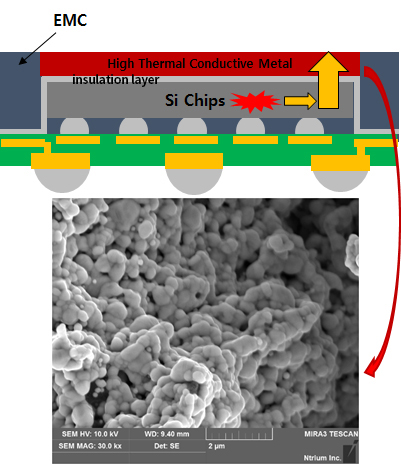

Recently, electronic devices used in automotive, electrical, and electronic fields are being lightweight, miniaturized, and multi-functional. As these electronic devices become more integrated, more heat is generated. By developing high thermal ceramic paste for spray, Ntrium provide optimized solution for new package structure.

Characteristics and Merits

- High Thermal Ceramic Paste (> 3.0W/mK) with high electrical insulation

- Good Spray Applicability - Good Workability / Uniform profile at both surface and edge

Line-up

| Products | NIS-S7B |

|---|---|

| Filler content | wt% = 89 Vol% = 74 |

| Specific gravity (g/cm3) | 1.68±0.1 |

| Solid content (wt%) | 61.5±1.0 |

| Viscosity(cps) | 62±10 |

| Cross-cut tape | >5B |

| Thermal conductivity (W/mK) | >3.0 |

| Resistivity (Ω·㎝) | >1.1 x 1013 |

| Breakdown Voltage (kV/mm) | >18 |

Application and Other Characteristics

> Cross-sectional FESEM image after spray