Paste for spray

E-Mail InquiryProduct Overview

The application of EMI shielding materials is indispensable to obtain high performance of ultrathin mobile devices,

and expanding to semiconductor packages, smartphones, displays, home network appliances, and automobiles due to improved materials and process technologies.

Ntrium has developed high conductive and high reliable materials for package-level EMI shielding, and has been approved for qualification and manufacturing

by global chip maker

and OSAT companies for the first time in the world.

Ntrium has secured the EMI shielding total solution that includes materials and process technologies based on years of steady research and development and accumulated technologies.

Characteristics and Merits

- First-ever approved EMI shielding spray materials for semiconductor packages in the world.

- Excellent properties such as shielding effectiveness, workability, adhesion and etc.

- High stability and storage reliability for long hours working at room temperature

Technical Data Table

| Products | NES-F3-0371 |

|---|---|

| Material | Ag |

| Volume Resistivity (Ω·㎝) | < 2.5 X 10-5 |

| Viscosity (cps) | 5,000 |

| Cross-cut Test | >5B |

| Curing Condition | 60 min@60℃ / 30 min@150℃ |

| Storage Temperature | Room temperature |

| Lifetime | 6 months |

Application

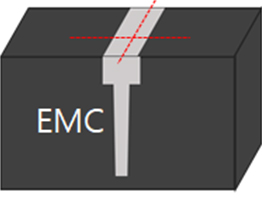

> Flow diagram for package-level spray process

- Tray loading &

Units transfer to wafer-ring

- Spray

- Curing

- Units transfer to tray again

-

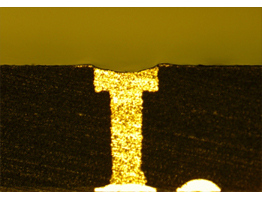

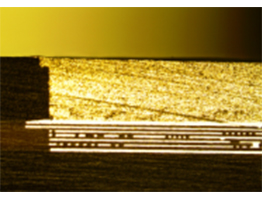

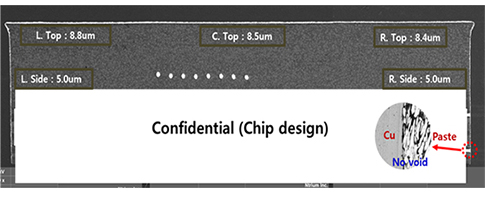

> Cross-sectional FESEM image after spray

-

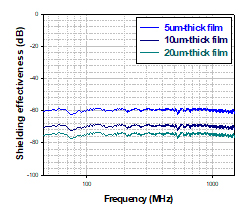

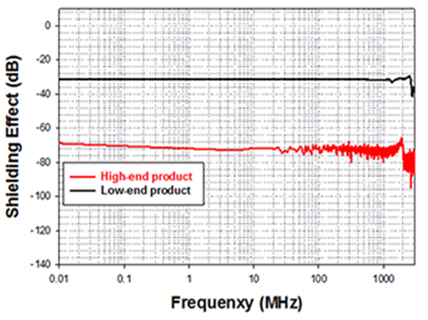

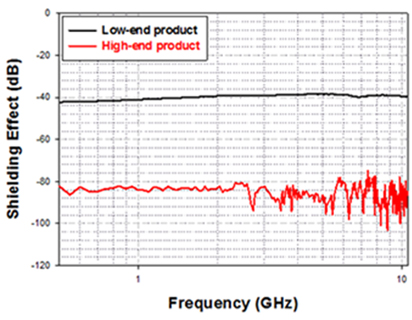

> Measurement result for shielding effectiveness